WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

At Williams Construction, we specialize in assisting your in-house team with anything from day to day maintenance needs and annual shutdowns, to emergency situations. Our team can work full-time, part-time, and alternate shifts depending on your needs.

Whether you operate a ball mill, ... Pinion maintenance can be one area of the mill's drive train that is often neglected by the ... Fixed Plant Maintenance ... CachedUsed Ball Mills Capacity Cost for Cement Plant in USA. ... In cement grinding plant, ball mill firstly .

Ball Mill. We bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications. Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality, and nature of raw material, site conditions and specific requirements.

Supplier of new parts for Bridgeport Series I Milling Machines, some used parts. We repair, rebuild and retofit mills, lathes grinders, presses, shears, CNC machining Centers and more. Sell used or new machinery by Sharp, Wells-Index, Ellis, Wilton, Jet, Powermatic, Performax. Digital Readouts by Acu-Rite, Anilam, Newall. Power Feeds by Servo, Align.

Ball mill maintenance,how to maintain ball mills. Ball mill maintenance. Ball mill is an efficient tool for grinding many materials into fine . motor and the transmission drive shaft coupling should maintain high .

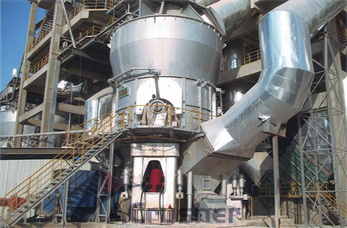

Mills are driven by a circumferential drive with a gearbox DMG 2 with two integrated pinions via a girth gear or with a gearbox, countershaft and one pinion for mills with a smaller diameter. An auxiliary drive is used for turning of the mill drum during maintenance. Mill shell Mill seating Mill drive Range of two-chamber mills

The auxiliary drive allows you to slowly turn the ball mill to evenly cool it or for maintenance tasks. It is equipped with a small planetary gearbox and a fluid coupling to minimise torque peak during start up and smoothly accelerate the mill.

COPPER MOUNTAIN: OVERVIEW ON THE GRINDING MILLS AND THEIR DUAL PINION MILL DRIVES ... SAG mill, ball mill, ring gear, dual pinion, drive systems, variable speed ... On a large dual pinion mill, using the ABB drive to rotate the mill for maintenance is an

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications.

offers AG mills, SAG mills, ball and pebble mills, and stirred mills to your needs. By continuing to use the site, you agree to the use of cookies. ... Our comprehensive line of grinding mills, spare and wear parts as well as maintenance and optimization services provide reliable and energy efficient technology and solutions across wet ...

the use o f a ball mill and maintenance functions the use o f a ball mill and maintenance functions SmartMill: Exceed your performance limits Take full control of your . In modern grinding, ball mills and SAG mills are two types of .. that the mill runs at its optimum .

700HP AC Variable Frequency Drive for positioning a MV synchronous motor driven ball mill. The Benshaw variable frequency drive powers the 4160Volt - 3500HP synchronous ball mill motor during positioning to smoothly rotate the ball mill and bring it to the proper position for maintenance.

Sepro Tyre Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications, and are suitable for Ball, Rod and Pebble charges. Sepro Grinding Mills come complete with a variable frequency drive (VFD) package which allows you to fine tune the operation of the grinding mill based on the charge and mining application.

V-BELT Ball Mill DRIVE V-belt or poly-V drives are generally used on grinding mills consuming 350 HP or less. Where power exceeds this, drives become so large and motors become special, resulting in an uneconomical application. Generally the driven mill sheave .

Aug 11, 2015· Ball Mill Preventive Maintenance August 11, 2015 03:06:27 PM Ball mill preventive maintenance (PM) It is a frequency work to maintain and repair ball mills, AG mills and SAG mills. The maintenance work influences the rotational speed and service life of ball mills.

The gearless mill drive is covering the upper power range of the mills. The torque is transmitted to the mill directly through the magnetic field in the air gap of the motor, eliminating the gear reducer, the ring-gear and the mechanical related issues faced by maintenance with ring-geared mills.

The motor can also be used to inch and spot the mill for maintenance. ... The SAG mill is followed by two 20-ft diam., 7,500-hp gear-driven ball mills. Another type of drive, less commonly used ...

We provide optimized mill drive solutions for all types of ring-geared mills: low and high speed, single and dual pinion, with and without a gearbox — all designed for reliable, long life and low maintenance operation. Video explaining ABB ring geared mill drive technology ... Fine-tuning of the speed in ball mills increases metals recovery ...

Selinsky FORCE 5365 E. Center Drive Suite C ... Defcon FORCE delivers the most comprehensive pulverizer, ball mill and crusher repair services on the market. Construction services for the industrial, oil and gas, and pulverizer industry. We have equipment .

Gearless Mill Drives Machinery Risk Solutions Practice 2009 Matt Dugalic P.Eng., MARSH ... SAN CRISTOBAL Bolivia Ball-Mill 22 7,830 2007 EL TENIENTE Chile SAG-Mill 38 19,400 2003 ... SIMINE Mill Gearless Drive Maintenance, Service. Page 24 October 2009 Kurt Tischler I IS MT MI

Ball mill maintenance Prime Machine, Inc. Ball mill maintenance our shop and field crews make a unique combination to provide complete and up to date ball mill maintenance services. The shop is fully equipped with the large machining, fabriion, and engineering capabilities to rebuild your mill components. Mill drive train alignment.

Variable frequency drive (VFD) for Chinaware ball mill With the world facing a growing energy crisis because of limited oil reserves and carbon emissions causing global warming, China is dedicated to optimizing its energy management.

2 d4 TM Mill Drivesystem 7 MW 7 MW 14 MW 28 MW 7 MW 4 MW 7 MW 7 MW 7 MW 4 MW 7 MW 7 MW SAG mill 32 ft. single drive The natural progression in gear/pinion mill drives: The QdX4TM Mill Drive provides the next step in the evolution of change in mill drive architecture, while allowing the system to be built with components that are within current manufacturing capabilities.

Jun 05, 2013· We provide optimized mill drive solutions for all types of ring-geared mills: low and high speed, single and dual pinion, with and without a gearbox — all designed for reliable, long life and ...