WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

One comment that I did not see here is the potential for differential grinding, especially in vertical mills, but also in ball mills. That is when inter-grinding different materials, the softer materials tend to be ground finer. In air swept vertical mills, this can leave a higher quantity of the harder to grind material in the mill.

Milling operations may be classified under four general heading as follows: Face Milling, machining flat surfaces which are at right angle to the axis of the cutter.. Plain or Snab Milling, machining flat surfaces which are parallel to the axis of the cutter.. Angular Milling, machining flat surfaces which are at an inclination to the axis of the cutter.

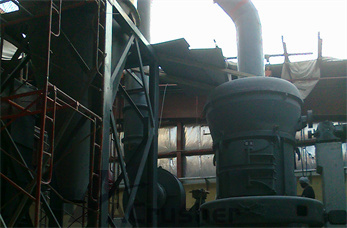

LM series vertical grinding mill is one advanced powder making mill which is developed through many years' research &experience and bringing in the latest mechanical techniques of Europe. It is one complete plant that integrated with drying, milling, classifier and elevator. It is the high standard mill with many advantages, like taking a ...

LM series vertical roller mill is one advanced powder making mill which is developed through many years' research &experience and bringing in the latest mechanical techniques of Europe. It is one complete plant that integrated with drying, milling, classifier and elevator. It is the high standard mill with many advantages, like taking a ...

classification of lm vertical mill - bgsgcollege. trommel for grinding - machinery required for cement. asphalt shingle grinding asg is produced by processing asphalt roofing shingles to a small spec,generally under 3 8 to salvage the t60 trommel screen. Get Price.

Jun 27, 2016· LM vertical roller mill, vertical mill is a mature technology, foreign successful experience and our technical innovation and upgrading the perfect combination of an energy-efficient mill .

End-milling cutters — End mills can be used on vertical and horizontal milling machines for a variety of facing, slotting and profiling operations. Solid end mills are made from high-speed steel or sintered carbide. Other types, such as shell end mills and fly cutters, consist of cutting tools that are bolted or otherwise fastened to adapters

SBM LM series vertical grinding mill is widely applied in metallurgy, construction, chemical and mining industries, being the preferred equipment in grinding industry. It can be used in grinding non-flammable and non-explosive materials with Mohs' hardness below 9.3, such as grinding quartz, feldspar, calcite, talcum, barite, fluorite, iron ...

Start studying manufacturing lab. Learn vocabulary, terms, and more with flashcards, games, and other study tools. ... two broad classifications of milling machines. fixed-bed and column and knee ... in feet or meters that a point (tooth) on the circumference of a cutter moves in one minute. scale on spindle head of a vertical milling machine ...

Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or irregular surfaces by feeding the workpiece against a rotating horizontal. These machines are also classified as knee-type, cutter containing a number of cutting edges. The milling ram-type, manufacturing or bed type, and planer-type. Most

The Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM 12.2 D to LM 20.2 D), with table diameters from 1,200 to 2,000 mm. Larger mills with two, three and four rollers and modular struc-tures (LM 21.2 D to LM 43.4 D), with table diameters from 2,100 to 4,300 mm.

room for particles to circulate during classification, as shown in Figure 2a. This makes the mill much taller than the vertical mill, but allows it to be closely coupled with a cyclone or filter-receiver when required. This mill's clas-sifier wheel and impact rotor have independent drives, and the mill can handle the same grinding ...

Jun 27, 2016· LM vertical roller mill, vertical mill is a mature technology, foreign successful experience and our technical innovation and upgrading the perfect combination of an energy-efficient mill equipment.

LM Vertical Grinding Mill. LM vertical grinding mill is our company on the basis of extensive use of advanced technology, combined with years of experience in production, design and development of an advanced ideal for large-scale grinding equipment.

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations.

Vertical Roller Mill, LM Vertical Roller Mill in China. LM Vertical Roller Mill LM series vertical milling machine, which is developed and launched by Zenith, sets medium crushing, drying, grinding, classifying and other functions as a whole, being the ideal equipment in the grinding industry.

LM Vertical Roller Mill. LM Vertical Grinding Mill integrates five functions of crushing, grinding, powder selection, drying and material conveying. It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protection.

product introduce: LM series vertical roller mill is a kind of advanced powder making equipment developed by introducing the latest mechanical technology of Europe after years of research and experience.It is a complete set of equipment integrating drying, milling, classification and promotion.With the advantages of small footprint, high efficiency and energy saving, LM vertical roller mill ...

Hot Sale: Integrates drying, grinding, powder selection and conveying together Applied to the non-metallic ore, coal powder and slag powder three fields. Heavy Industry actively absorb successful abroad experience, and through the continuous technological innovation and upgrade of the R & D team, launched with independent intellectual property products: LM vertical mill.

1980 Delivery of first modular coal mill (LM 26.3 D) 1965 Construction of first pressure mill (LM 12.2 D) 1961 Introduction of hydraulic spring assembly system 1953 th500 coal mill plant sold worldwide 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin We have been successfully involved in the grinding of solid

Jan 31, 2016· Milling is basically known as most common type of machining process of removing the unwanted material from workpiece. Workpiece will be machined by inserting against one rotating cutter and rotating cutter will have a number of cutting sharp edges.

What Is a Milling Machine Used For? What Is a Milling Machine Used For? ... Milling machines can take on vertical and horizon positions, depending on their intended use. They use rotary cutters to cut and shape while a piece of the material is fed in one direction. Computer numerical controlled machines can automatically change the tools used.

LM series vertical mill is one advanced mill, adopting top technology domestic and abroad, and based on many years' mill experiences. It can crush, dry, grind, and classify the materials. LM series vertical milling machine can be widely used in such industries as cement, power, metallurgy, chemical industry, non-metallic mineral.

LM series vertical milling machine - Mobile Cone Crusher. LM series milling machine is in the relevant vertical mill technology matured, vertical mill products under the technical superiority of .