WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Jet Pulverizer, Inc. offers three different types of mills, each with its own unique characteristics and operational advantages. Selecting the most appropriate type of mill, size and materials of construction allows a user to specify a Micron-Master® pulverizer that .

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (e.g., via a hand crank), working animal (e.g., horse mill), wind or water ().

Machining. Machining is manufacturing process that involves removing materials using cutting tools for getting rid of the unwanted materials from some workpiece and converting it into the shape you desire. A large piece of stock is used for cutting the workpiece. The large stock might be in any shape such as solid bar, flat sheet, beam or even hollow tubes.

Apr 07, 2015· Advantages and Disadvantages of Milling Machine. Posted on April 7, 2015 March 3, 2019 by Peter Paul. Milling is a process of removing metal by feeding the work against a rotating multipoint cutter. The machine tool intended for this purpose is known as milling machine.

The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill. AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

Feb 11, 2015· TYPES OF MILLS The different types of mills used in fine grinding are as follows: The Hammer Mill High Impact Turbo Mill Pin Mill The Vibrating Mill Stirred Media Mill Fluid Energy Mill Here after, we will concentrate on Pin Mills. 5. PIN MILL Pin Mills are type of Disc Grinders. Also known as Centrifugal Impact Mills (CIM) Pin mills are a type ...

Different types of grinding mills are discussed bellow along with their purposes. Ball grinding mill: ball mills are the most common ones. They have horizontal cylinders filled with metal balls. The cylinder rolls around creating a friction and impact with the balls. The impact then crushes and .

These mills are of a special design and described on special request by all Ball Mill Manufacturers. Types of Grinding Mill Manufactured. The different types of grinding mills are based on the different types of tumbling media that can be used: steel rods (rod mills), steel balls (ball mills), and rock material (autogenous mills, pebble mills).

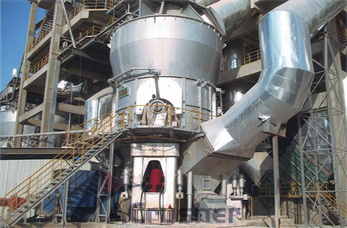

Grinding Mill. XSM grinding mills vary from coarse grinding, medium grinding to micro fine grinding.Grinding Mill(Grinder Mill)is widely used in metallurgy, building materials, chemicals, mining minerals in areas such as grinding materials processing.The materials include line, calcite, barite, coal, gypsum, mica and bentonite powder.

Oct 21, 2017· Grinding mill has widely application in the field of slag, coal mine, cement, non-metallic mineral and other industries, Fujian Fengli produced slag grinding mill has many advantages and.

For the preparation of small quantities of powder many types of mill are available but, even so, the ball mill is frequently used. For the grinding of the largest quantities of material however, the ball, tube or rod mill is used almost exclusively, since these are the only types of mill which possess throughput capacity of the required magnitude.

That is a beautiful mill! I too love the smell of fresh flour – it's one of my favorite smells and reminds me of growing up since my mom was often grinding wheat to make bread. I have been grinding my own wheat for years but have never tried grinding any other type of .

Through-feed grinding, end-feed grinding and in-feed grinding are three types of centerless grinding and have certain disadvantages to the production process. Through-Feed Grinding Disadvantage Workers use through-feed grinding to grind cylinder type objects by rotating them between the grinding and rotating wheels.

Hammer mill is the most widely used grinding mill and among the oldest. Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case.

A typical hammer mill has a sturdy body, and comes in different types and sizes. There's also an automatic option should you want to automate your grinding process. The number of hammers in a hammer mill is completely customizable. Its use increases the output by a large quantity, thus saving more time and energy. Advantages of Using the Hammer ...

Advantages of steel slag vertical grinding mill system. Advantages of steel slag vertical grinding mill system News Date:2018-08-20 14:13:30. Steel slag is the waste residue generated by decarburization, dephosphorization and desulfurization of iron extracted from blast furnace during steel making.

Dec 21, 2016· Grinding of minerals are carried out in the mills. There are different types of the grinding media used in grinding. ... Types Of Grinding Media. ... specialists of Energosteel company will hold for you a more detailed comparative analysis of the most common grinding media, marking the advantages and disadvantages of each.

Apr 16, 2016· There are different types of windmills, Which windmill to use is dependent on the requirement. Wind turbines It is a three rotor designed windmill, This windmill are used to convert the kinetic energy i.e energy of motion of the wheel due to wind into mechanical energy.It is connected to a generator which converts into electricity.

Pharmaceutical manufacturing companies can choose from ball mills, field energy mills, cone mills, turbo mills and hammer mills. Here is a breakdown of the most commonly used grinding mills in the pharmaceutical industry: Ball Mill. A ball mill is a type of pharmaceutical grinding mill which uses either rubber, porcelain, metal or steel balls.

different types of grinding mills advantages -, Mill (grinding) - Wikipedia, the free encyclopedia A grinding mill is a unit operation designed to break a solid material into smaller piec There are many. mineral processing ore types of ball mills - phspipeline.

May 02, 2017· These machines are available in different shapes and size according to requirement of the process and due to technical issues. Every rolling mill consist minimum two rolls. These numbers can extend according to the process requirement. Today we will discuss about all types of rolling mills used in manufacturing industries.

Article on grinding machine, types and uses of a grinding machine, manual surface grinder, manual surface grinding machine including hydraulic surface grinding machine, cylindrical grinder, cylindrical grinder machine, centerless grinding, centerless grinding machine for automobile, electronic, electrical and engineering industries by leading distributors of machine tools, Bhavya Machine Tools ...

Selecting The Right Mill For Your Needs Jet Pulverizer, Inc. offers three different types of mills, each with its own unique characteristics and operational advantages. Selecting the most appropriate type of mill, size and materials of construction allows a user to specify a Micron-Master® pulverizer that is essentially a custom design ...

Sep 3, 2015 Synchronous Motors on Grinding Mills The Different Excitation Types and Resulting Performance Characteristics with VFD Control for New or Retrofit Installations. Abstract Synchronous motors (SMS) continue to be a viable alternative to induction motors because of efficiency advantages.